PW Gadgets

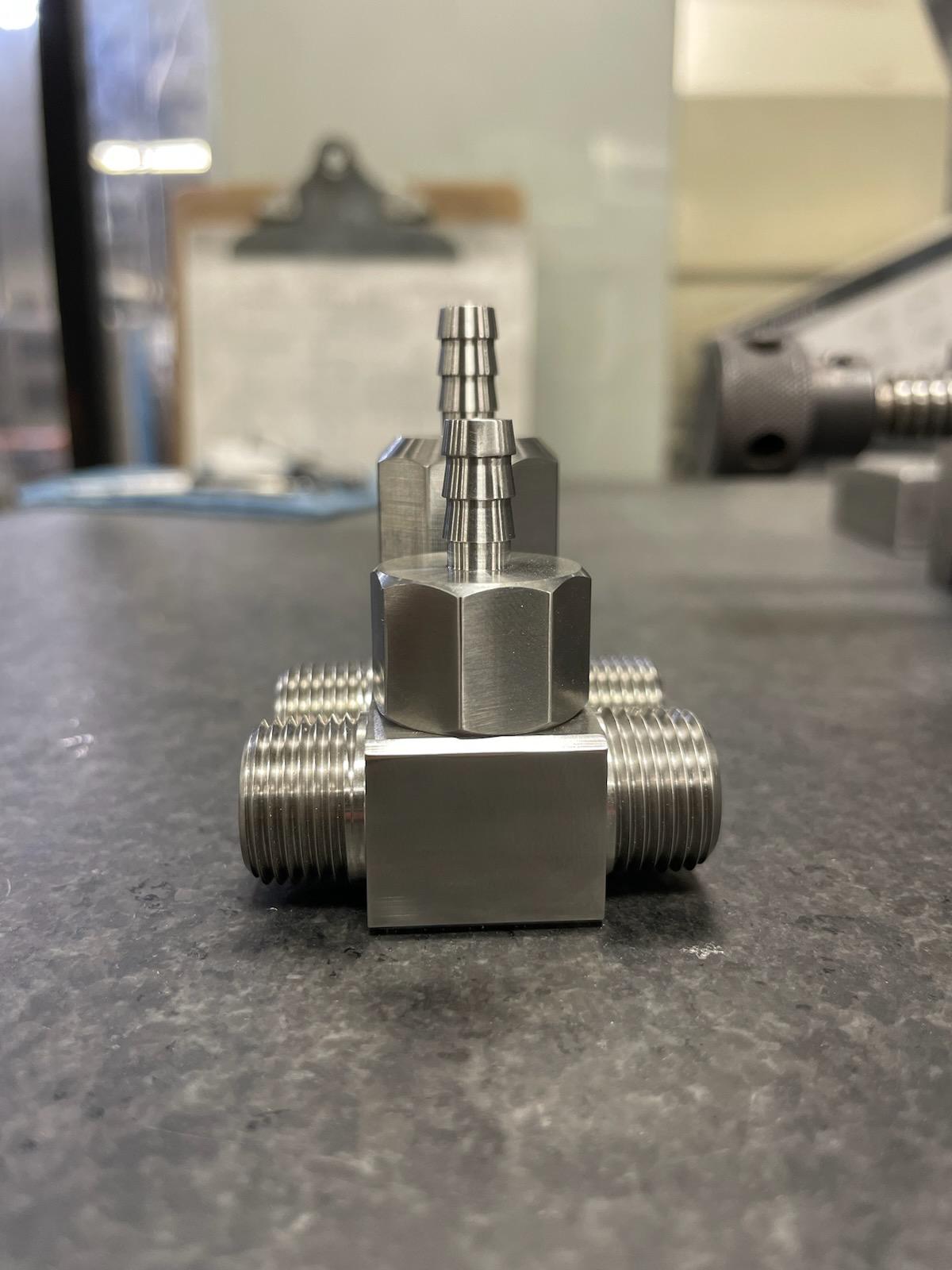

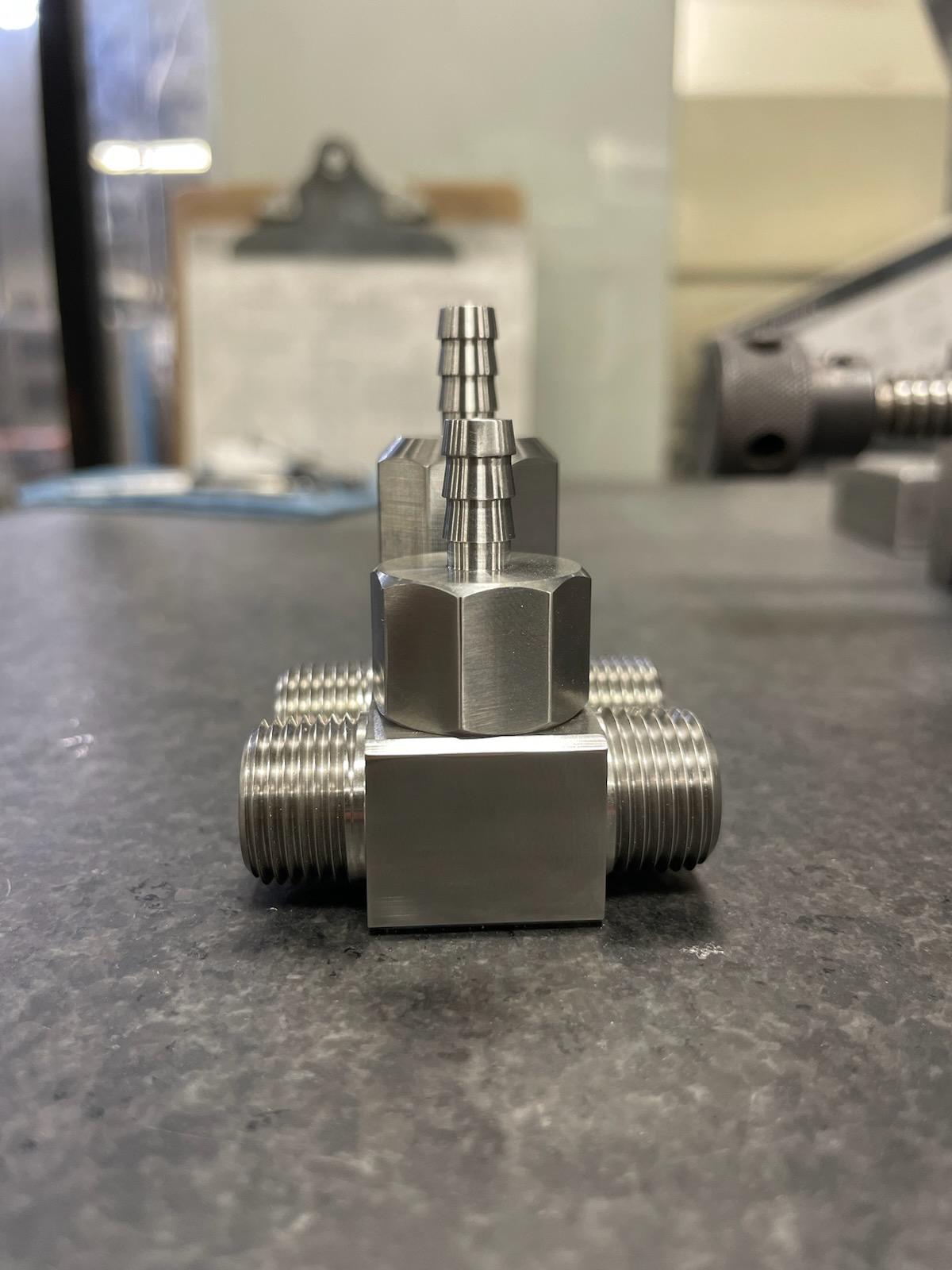

The GOLD Standard Downstream Chemical Injector Gen 2

The GOLD Standard Downstream Chemical Injector Gen 2

Couldn't load pickup availability

Thank you for allowing me to introduce you to our Flagship a TRUE high pressure downstream chemical injector. I choose to use the word true because ALL other injectors have continual problems with their tiny ball, small metal spring and undersized o-ring design. It is my opinion that they were meant to be used on the vacuum side of the pump and not the high pressure side. Soft elastomers are not well suited to catch a speeding projectile AND handle the force of 4k psi pressing on its face. They will tear, split, roll, etc. We aimed for superior longevity, The GOLD Standard injector does NOT use an o-ring for a main seal NOR does it have an internal spring for the check valve. The check valve body contains a diamond polished Ceramic ball that seals against an engineering plastic with a very HARD seat! I looked carefully at every commercially available injector and noticed a fair bit of inconsistency in each of their manufacturing process. Have you ever tried an injector that didn’t pull like the last one even though they were identical? Several injectors I looked at fell out of their own tolerances. These injectors were CNC milled and THEN turned on a CNC lathe for consistency! We are holding very tight tolerances so they ALL work well for as long as they possibly can before they fall out of tolerance. This injector was modeled to solve all the issues on the check valve. We were elated to learn that the chemical flow rate improved as a direct result of our very free flowing check valve design. But alas this injector was created to solve the issue of poor reliability so one could can work MORE with LESS problems. When you fire up a up machine you want it to start and run problem free until you say when right? I feel this injector will solve that issue for you! We have since moved on from the Gen 1 to the Gen 2 you are currently viewing here. Honestly we didn't think there was much to improve upon but here at PW Gadgets if we can ever go back and improve something even just 1% we're taking that opportunity. We shortened the travel distance of the Ceramic check ball, shaved a few threads, and basically just gave it a haircut. The Gen 2 will use the same rebuild kits as the Prototype and Gen 1 GOLD Standard injectors.

Let's talk dilution ratios! The GOLD Standard injector will pull a extremely rich 5.4:1 ratio!

5.4:1 ratio on a 4gpm (94.5 ounces a minute)

5.5:1 ratio on a 4.75gpm (94 ounces a minute)

and we are getting reports of 13:1 ratios on 8.5gpm machines

We understand this could be a bit too much chemical for certain scenarios. The hose barb has been internally threaded for use with the proportioning tips that are available through us so one could meter how much SH is pulled into the stream. Simply thread in a metering tip that only allows a lean flow of chemical for a standard house wash and then simply pull out that tip and immediately have a much stronger mix for stucco, etc.

If you're not quite convinced this is a solid performer, I leave you with this...The GOLD standard injector continued to pull well despite being installed in front of 430+ feet of 3/8" pressure hose!

In depth video of the Gen 1

https://youtu.be/RE7Xp42kBKg